High frequency plywood chair press and bending macine , also known as high frequency press, wood bending machine,high frequency wood bending machine, bentwood press,high frequency press, laminated high frequency wood bending press.

The equipment can be used in a variety of forms such as a high-frequency heating machine provides heating engery for one set press, two sets press, three sets press and four sets press at one time; the press uses a hydraulic system in one-way and three-way forms, which can meet the needs of different workpieces.

Using high frequency heating, it only takes 1 to 3 minutes. Compared with traditional steam heating, the bonding strength is higher, the shape is good, the speed is fast, and the quality is good. Especially for thicker workpieces, it shows the superiority of high frequency heating.

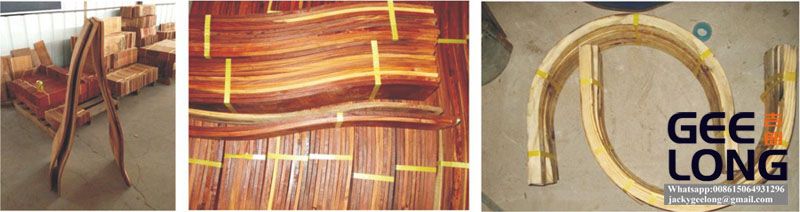

At present, this machine is widely used in wood bending processing related fields such as furniture manufacturing, musical instrument production, shoe material processing, and handicraft production.

High frequency plywood chair press and bending macine Advantage:

1) Penetrating uniform heating, heating time from tens of seconds to several minutes

2) Even heating is not easy to crack

3) Good stability, bent wood will not deform for a long time after molding

4) Using wooden molds, low replacement cost

80T High frequency plywood chair press and bending macine specification:

working platform size:1100×650mm;

Openning:1800mm;

Max. pressure:80T;

Cylinder Quanity:2pcs;

Cylinder stroke:1200mm;

Machine power:5.5kw;

Working way:pressure from up to bottom

Machine Frame:steel plate

without mold