| Name | Parameters |

| cutter roller diameter | 800mm |

| cuter roller length | 850mm |

| production capacity(Max) | 38 cbm per hour |

| material inlet(heightxwidth) | 240x750mm |

| flying knife quantity | 2pcs |

| cutter roller running speed | 650r/min |

| feeding speed | 39meter/min |

| main motor power | 132kw |

| feeding roller motor power | 4x2kw |

| oil pump motor power | 0.55kw |

| finished wood chips length | 30mm |

| main mahcine dimension(lengthx width x height) | 4670x2150x1500mm |

| machine weight | 7300kgs |

| static load | 71.50KN |

| dynamic load | 179KN |

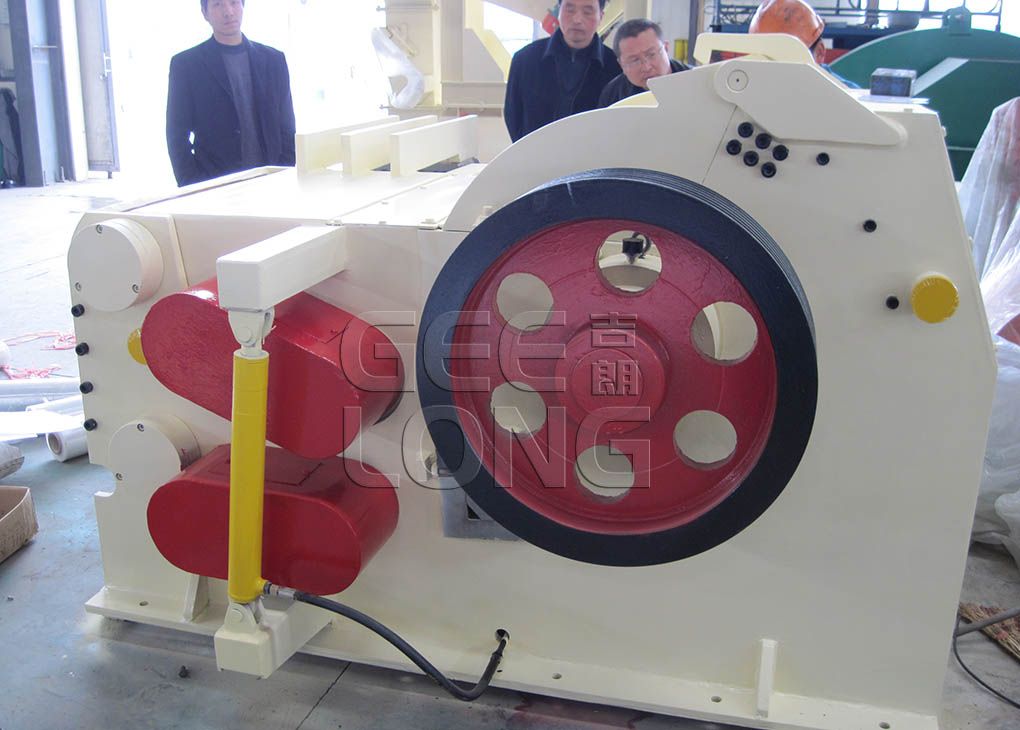

The Drum Chipper is the special equipment which used for reducing kinds of wood (tree limbs, trunks, whole logs, pulp wood, veneer, solid wood, cores, slabs, scraps, etc.) into smaller and quality wood chips, which is used as material in pulp & paper industry, biomass industry, fiber and particleboard plants, and also well suitable as fuel for high intensity burning in modern heating plants.

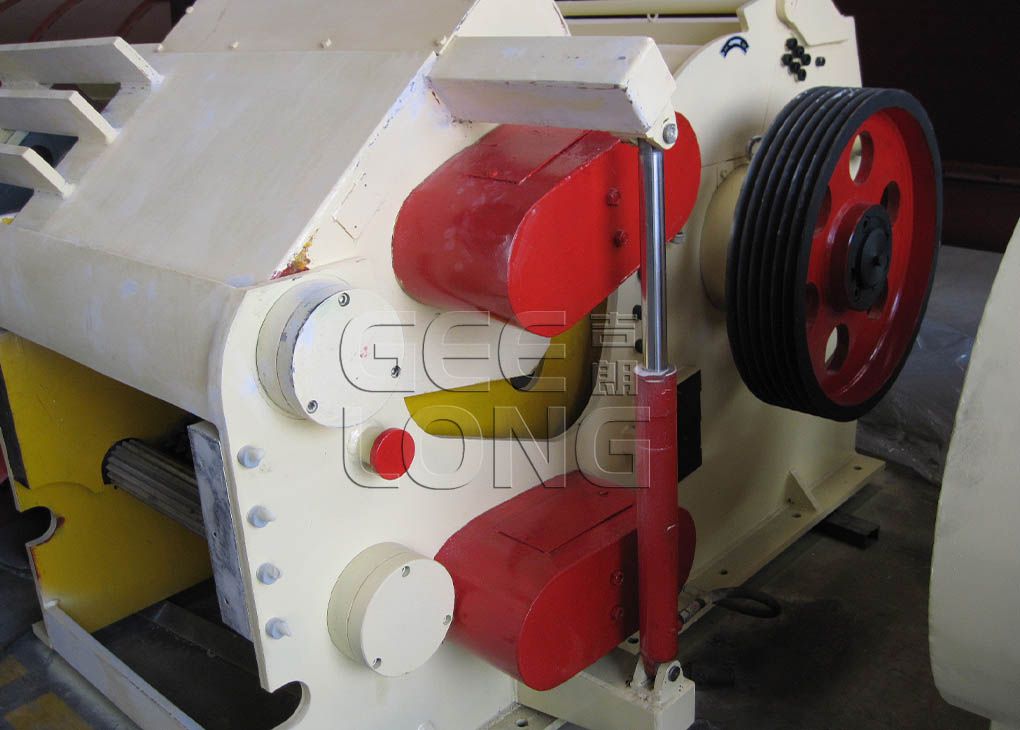

The complete set of this type of machine contains: machine base, rotor drum, upper and lower feed rollers, electrical motor, fed-in belt conveyer, hydraulic sustem, etc. The machine base is welding of high quality steel plate serving as a support of the whole machine.

The process of chipping is fairly straightforward: The feeding system draws wood materials in, and the revolving drum (with fly knives on) cut the woods then chips fly out from the bottom of the machine. The common dimension of final chips is 15-40 mm. The chip size could be controlled via adjusting the counter knife.

The drum is mounted at the center of the machine and serves as the feed mechanism. It is powered by a electrical motor, usually by means of a belt. With a feed and control system, this type of chipper could handle woods efficiently and safely, there will be less downtime and will get more consistent final chips.

For the advantage of high capacity, reliablility and low maintenance requirements, the drum machine is becoming more and more popular in modern industry.